V-ribbed belts or multi-rib belts are used in many mechanical applications and are considered to be very important. These belts are intended to offer high performance due to the balance between flexibility and strength. Regardless of whether it is an automobile engine or industrial equipment, people highly estimate their valuable features to transmit power. The present article aims to discuss the main features of the V Ribbed Belt with an emphasis on their flexibility, durability, and versatility.

The Structure of V-Ribbed Belts

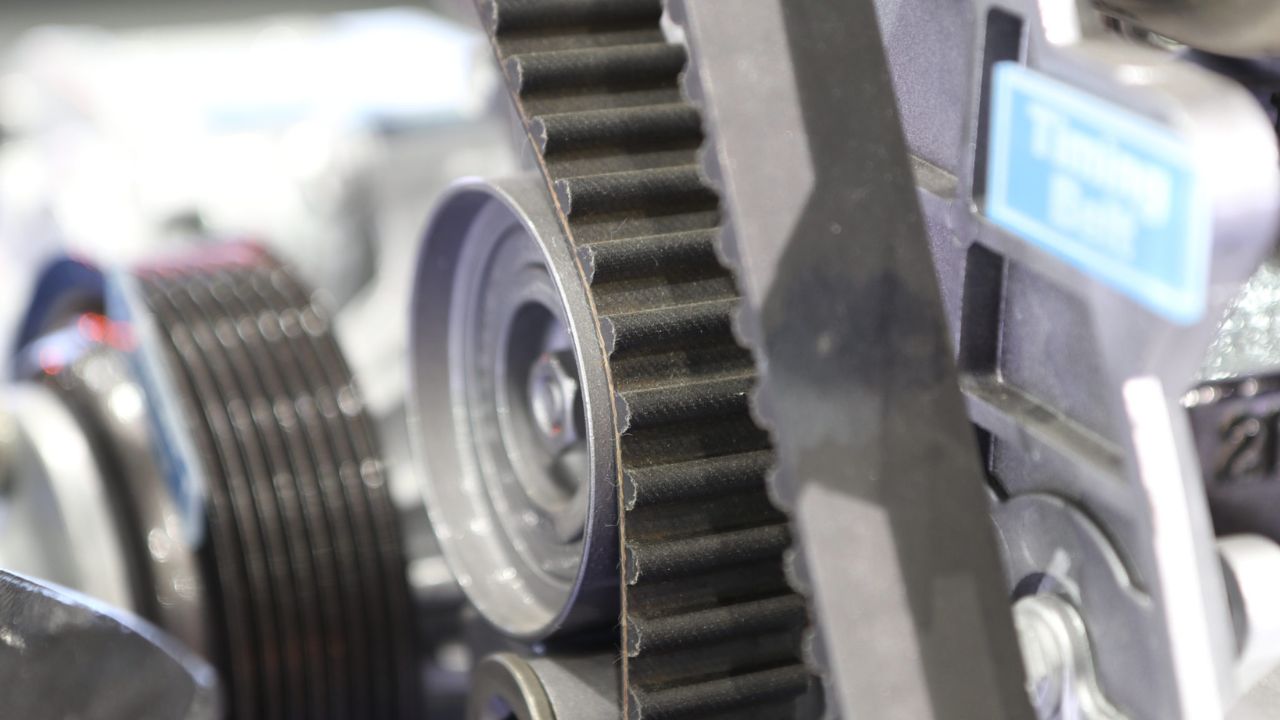

The design of V-ribbed belts is unique as compared to other belt types. These belts have a flat wide shape with several longitudinal grooves on the bottom side. The ribs are intended to be closely engaging with the grooves of pulleys so that they can have a good grip on the pulleys. V-ribbed belts include synthetic rubber, polyester cords, and fiber reinforcements thus achieving flexibility with adequate power transmission. This innovative structure enables high efficiency of power transmission, low vibration, and smooth running of the equipment. The design also reduces the chances of slippage and guarantees reliability in extreme conditions.

Flexibility: Adapting to Complex Systems

Since the invention of V-ribbed belts, notable unique characteristics include the great flexibility of belts. These belts can easily weave through the complex V-shaped pulley system with some bends and other turns as compared to conventional V-belts. They are suitable for modern machinery, which requires small designs due to their flexibility in small spaces and ability to work with pulley diameters of different sizes. For instance in automobiles, V-ribbed belts are used to drive several accessories including; alternators, water pumps, and air conditioning compressors all on a single belt. They are flexible enough to run the operations smoothly and eliminate the need for several belts, which makes it easy to maintain them and therefore cut costs.

Durability: Designed for High Stress

Yet another element of V-ribbed belts is their durability. These belts are designed to offer high levels of working capacity which makes them ideal for heavy-duty operations. The manufacturing processes and the quality of the material used in the V-ribbed belts guarantee that they can withstand high temperatures, and high levels of abrasion and still perform well under high loads. These belts feature fiberglass-reinforced rubber for superior tensile strength, and ribs to help absorb the stress on the material of the belt. This decreases the chances of early failure thus increasing the belt’s durability and reducing the time the belt is off.

Versatility: Different Sectors

The flexibility of V-ribbed belts makes them essential in many sectors of the economy. In automotive applications, they are very popular in the serpentine accessory drive where they play an important role in making most of today’s automobiles more efficient and reliable. At workplaces, they drive conveyor systems, and air conditioning among other equipment to enhance productivity. Also, V-ribbed belts are used in home appliances like washing machines, and dryers due to their compactness and low noise production. This makes them popular with many different uses since such characteristics as adaptability and reliability are essential.

Conclusion

V-ribbed belts can be considered a worthy candidate for the role of a power transmission solution. The two characteristics make them suitable for meeting the requirements of intricate, high-reliability systems. As the industries continue to grow it will become even more important to have V-ribbed belts to ensure that there is efficiency and reliability hence making them an important part of mechanical systems today.