In the modern industrial landscape, forging technology has evolved significantly to meet the demands of various industries. Among the different forging methods available, cold forging technology stands out as an environmentally sustainable solution that offers numerous benefits. In this article, we will explore the environmental advantages of cold forging, emphasizing its role in reducing waste, conserving energy, and promoting sustainability. By adopting cold forging techniques, any forging manufacturer can optimize the use of resources, resulting in not only cost savings but also a substantial decrease in environmental impact.

Reduced Material Waste

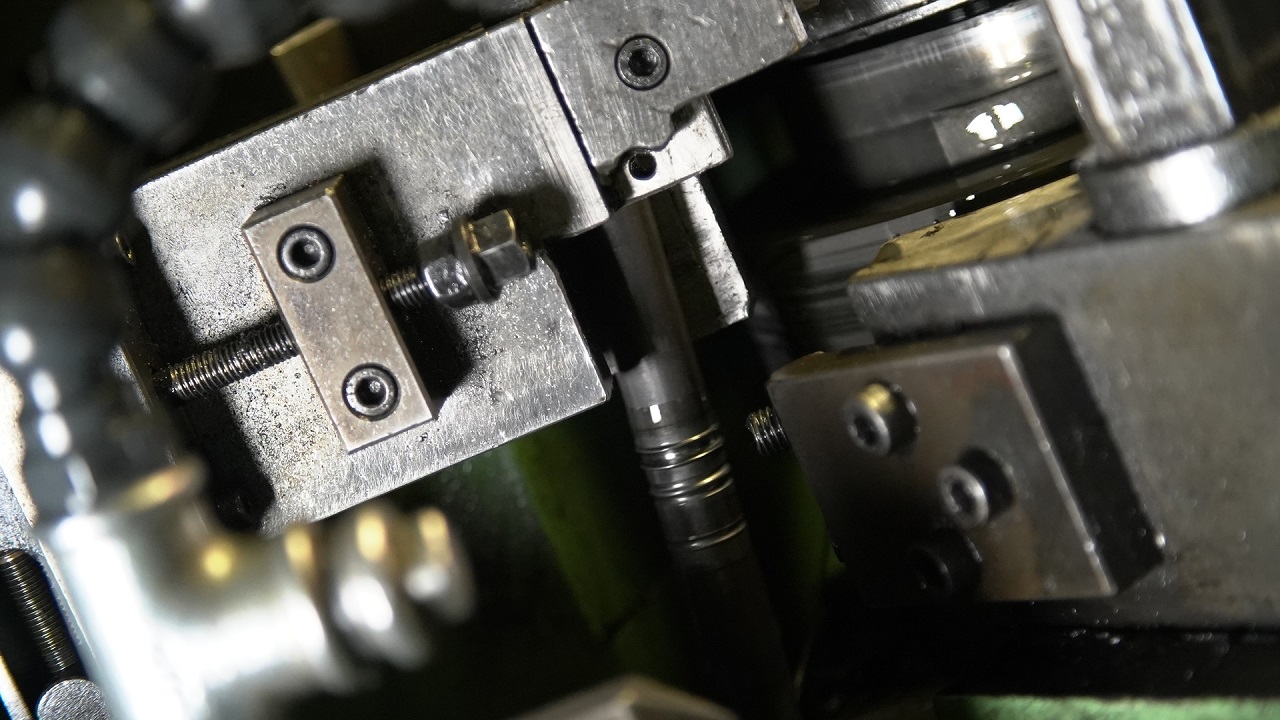

One of the foremost environmental benefits of cold forging technology is its ability to minimize material waste. Traditional machining methods often produce substantial waste in the form of chips and scrap materials. In contrast, cold forging is a precision manufacturing process that shapes metal parts by subjecting them to extreme pressure without the need for excessive material removal. This means that less raw material is wasted during production, leading to significant reductions in material consumption.

Energy Efficiency

Cold forging technology also contributes to environmental sustainability through its energy-efficient operations. Unlike hot forging, which requires heating metals to high temperatures, cold forging is conducted at or near room temperature. This fundamental difference translates into significant energy savings.

The heating process in traditional hot forging consumes substantial amounts of energy and contributes to greenhouse gas emissions. In contrast, cold forging reduces energy consumption, leading to a smaller carbon footprint. As the world becomes increasingly conscious of the need to reduce energy consumption and combat climate change, the energy-efficient nature of cold forging makes it an environmentally responsible choice for forging manufacturers.

Lower Emissions

Cold forging technology generates fewer harmful emissions compared to traditional forging methods. Hot forging involves heating furnaces that release pollutants into the atmosphere, including greenhouse gases and other pollutants. These emissions contribute to air pollution and have adverse effects on air quality and human health.

Cold forging, on the other hand, eliminates the need for high-temperature heating processes, resulting in lower emissions of pollutants. By adopting cold forging techniques, forging manufacturers can contribute to improved air quality and reduced environmental pollution, thereby supporting broader sustainability goals.

Longer Tool Life

Another environmentally beneficial aspect of cold forging technology is its longer tool life. Cold forging tools typically experience less wear and tear compared to their counterparts used in hot forging. This increased durability means that tools need to be replaced less frequently, reducing the demand for raw materials used in tool production.

Prolonged tool life not only minimizes the environmental impact associated with tool manufacturing but also reduces the disposal of worn-out tools, which can be an environmental concern. This aspect of cold forging aligns with the principles of sustainability by promoting resource conservation and reducing waste in the forging industry.

Conclusion

Cold forging technology offers a range of environmental benefits that make it a responsible choice for forging manufacturers. Through reduced material waste, energy efficiency, lower emissions, and longer tool life, cold forging contributes to a more sustainable and eco-friendly forging industry. As the world strives to address environmental challenges and promote sustainable practices, the adoption of cold forging technology represents a positive step toward reducing the environmental footprint of the manufacturing sector.